Catalytic Converter

Catalytic Converter

Introduction to this product:

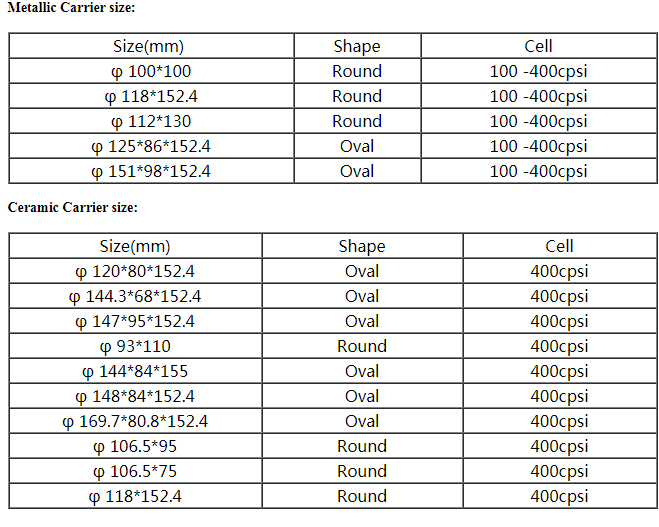

Our three way catalyst of autos employs metals or ceramic as the carrier, adding the self-made rare-earth coupound oxide as the accessory ingredient and a small amount of precious metals, thus is ultimately sintered after a special coating process. This product is not disposed to reduction.

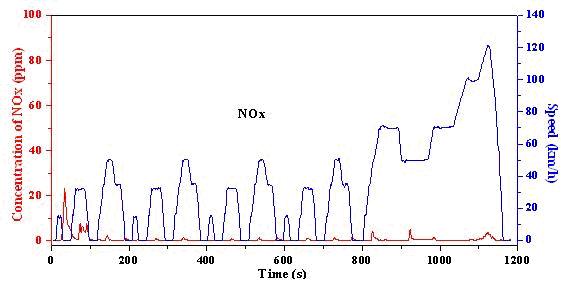

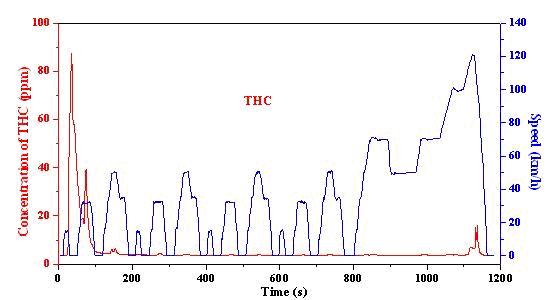

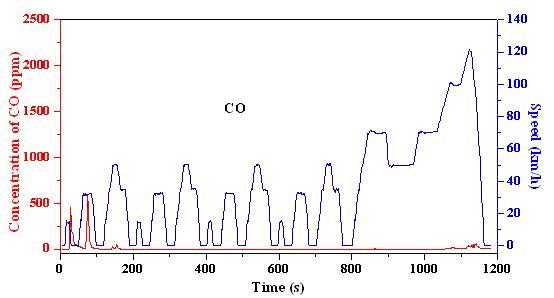

The catalyst has made full use of the coordination effect of precious metals and rare-earth coupound oxide, under the influence of which the Carbon Oxide(CO), Hydrocarbon(HC) and Oxynitride(Nox) in the tail gas of autos is oxidized and deoxidized. In this way, the three pollutants are converted into Carbon Dioxide(CO2), H2O and Nitrogen which are harmless to the air.

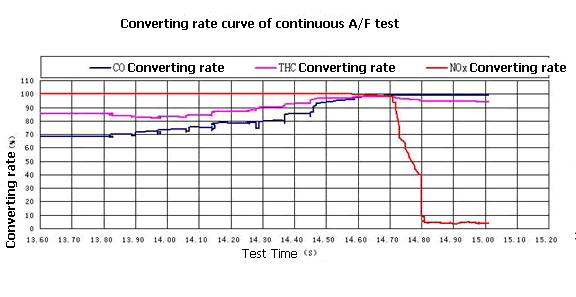

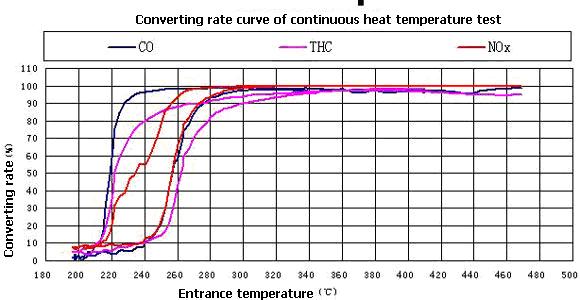

After 100 hours of bench rapid aging test in the automobile engineering department of Tsinghua University, the fractional conversion rates of CO, HC and Nox are 96.3%, 94% and 90.5% respectively. The lowest initial ignition temperatures of the catalyst are 235℃, 272℃ and 230C℃ which have risen by 45℃, 53℃ and 40℃ respectively, compared with fresh catalysts after the aging reaction and the aging coefficient is 1.2 accordingly. After tested on autos, it proved to have met EuⅡEmission Standard.

With the enforcement of Eu Ⅲ Emission Standard and Eu Ⅳ Emission Standard in China, Company has optimized the ingredient and developed a series of new catalysts with lower intial ignition temperature, higher conversion efficiency and higher resistant index under sintering and then applied for the National Patent for invention. The adjustments of engines according to the CCC+UCC or UCC Program enable the ingredient of tail gas to meet Eu Ⅲ Emission Standard and EU Ⅳ Emission Standard. In 2006, the ingredient of the tail gas was inspected in the national quality inspection center of autos and the cotents of CO, HC and Nox were 1.0g/km, 0.6g/km and 0.08g/km respectively, which had met Eu Ⅲ Emission Standard.