China OEM Plastic Mold Suppliers – Circuit breaker housing – Sino Vision

China OEM Plastic Mold Suppliers – Circuit breaker housing – Sino Vision

China OEM Plastic Mold Suppliers – Circuit breaker housing – Sino Vision Detail:

The miniature circuit breaker has the characteristics of advanced structure, reliable performance, strong breaking capacity and beautiful appearance. It is mainly used for AC 50HZ or 60HZ, with rated voltage less than 400V and rated current below 63A. It can be used for overload and short circuit protection of lighting, distribution lines and equipment in office buildings, residential buildings and similar buildings, as well as infrequent on-off operation and conversion of lines. It is mainly used in various places such as industry, commerce, high-rise and civil residence.

BMC process is characterized by:

(1) Easy to operate. The whole production process is easy to realize mechanization and automation, has high production efficiency, and improves the working environment and working conditions of wet forming.

(2) The product is highly unpredictable. The different requirements of different products can be met by changing the type and formula of components and changing the molding process. Such as corrosion resistance, insulation, heat insulation, zero shrinkage, flexibility, low density, high strength, class a surface, antistatic, etc.

(3) Good molding fluidity. It can form products with complex structure, especially suitable for making large thin shell special-shaped products. It can realize the functions of variable thickness of products with inserts, holes, bosses, stiffeners, threads and so on.

(4) The product is bright and clean inside and outside and accurate in size. It is suitable for making automotive peripheral parts, electrical parts, mechanical parts, anti-corrosion containers and other products. Suitable for large-scale production and low cost.

(5) The reinforcing material has no damage in the process of production and molding, uniform length and high product strength. It can carry out light structural design and bright color.

Everything is divided into two, and BMC process also has its shortcomings, mainly because BMC units, presses and molds require high investment, and high production technology requirements.

There are many kinds of molding methods. This refers to metal to mold hot pressing. This process is a method of forming products under a certain temperature and pressure when a certain amount of molding material is put into the metal to mold. The mold is in a non closed state before the molding material fills the mold cavity.

The molding process has the advantages of high production efficiency, mechanized and automatic production, accurate product size, smooth internal and external surfaces and low price. Most products with complex structure can be formed at one time without auxiliary processing (such as turning, milling, planing, grinding, drilling, etc.). The disadvantage is that the one-time investment is high, mainly because the press and mold are expensive, which is suitable for mass production.

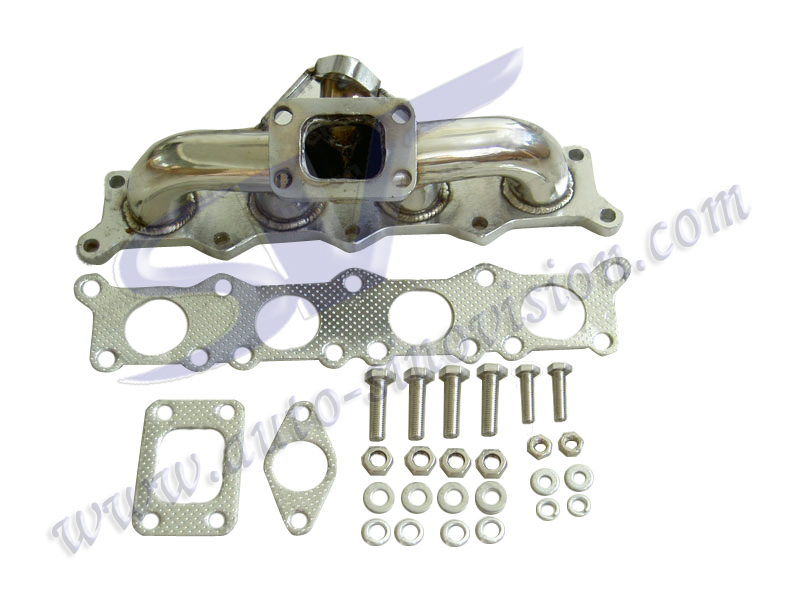

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for China OEM Plastic Mold Suppliers – Circuit breaker housing – Sino Vision , The product will supply to all over the world, such as: Israel, Ukraine, Panama, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.