China OEM Plastic Parts Of Spray Gun Suppliers – Post treatment device for primary muffler of diesel generator set – Sino Vision

China OEM Plastic Parts Of Spray Gun Suppliers – Post treatment device for primary muffler of diesel generator set – Sino Vision

China OEM Plastic Parts Of Spray Gun Suppliers – Post treatment device for primary muffler of diesel generator set – Sino Vision Detail:

The DPF selected by the company has the following characteristics:

1: The coefficient of thermal expansion is relatively small, with good high temperature resistance and thermal shock resistance

2: The filtration has large specific surface area, uniform micropore distribution and high pore attack rate

3: Small back pressure

4: The product has good durability

5: The filtering effect of soot particles is high, generally more than 90%, and is suitable for a variety of regeneration methods

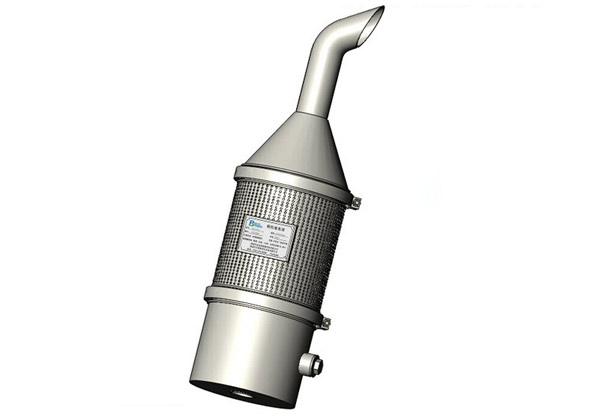

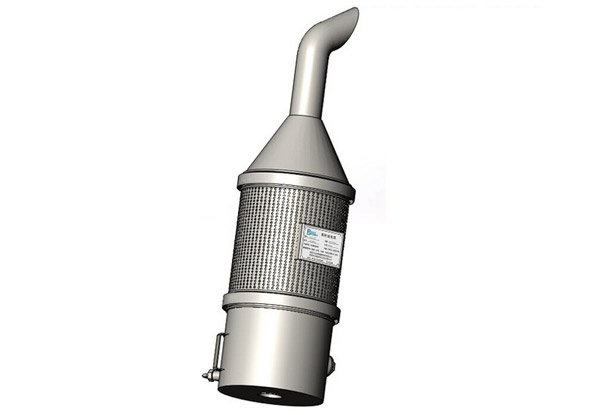

exhaust gas purifier (active regeneration + remote monitoring)

Composition of diesel engine exhaust purifier

It is composed of oxidation catalyst (DOC), particle trap (DPF), fuel injection system (high temperature cleaning device) and electronic monitoring and control unit. Diesel engine exhaust purifier capable of realizing active regeneration without additives. The remote monitoring function can be realized, and the mobile terminal and PC terminal can be monitored at the same time.

Workflow:

Carbon monoxide (CO) and hydrocarbon (HC) emitted from diesel engine are reduced by oxidation catalyst (DOC), and then ultra-fine nano soot particles (PM) are captured in DPF through honeycomb ceramic wall flow particle trap (DPF), so as to reduce the emission of polluting gas and soot particles. The electronic control unit monitors the pressure value in the system in real time. When the pressure value in the system reaches the regeneration set value, the electronic control unit automatically controls the high-temperature cleaning device to increase the temperature in the system and fully restore the particles captured in the DPF, so as to achieve the purpose of automatically cleaning the particle trap. The system can be reused for a long time.

Scope of application: diesel internal combustion engine machinery such as forklift, crane, excavator, bulldozer and stacker

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for China OEM Plastic Parts Of Spray Gun Suppliers – Post treatment device for primary muffler of diesel generator set – Sino Vision , The product will supply to all over the world, such as: Czech, United States, Argentina, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.