In case of air lines or jet lines near the rubber inlet of injection molded parts during production, the following analysis can be referred to for comparison and improvement. Among them, reducing the injection speed is the primary means for us to improve the problem of injection lines and air lines, and the second is to check whether the size of the injection molding part’s rubber inlet is too small or too thin. Baking good raw materials is the basic action to ensure production, and must be done well.

There are some differences in the appearance of glue inlet air lines and jet lines caused by various reasons. Pay more attention to observation at ordinary times, which can speed up the analysis and solution of problems.

If the raw materials for PC production have been fully baked, or there will be air or shoot lines at the water inlet, the following factors should be considered:

1. The first level glue injection speed is too fast. This is the main reason for the air mark when entering the water. It causes serious eddy current when the melt adhesive enters the cavity, resulting in eddy air mark. Therefore, this is the first thing that the shunter should consider and try to reduce the speed.

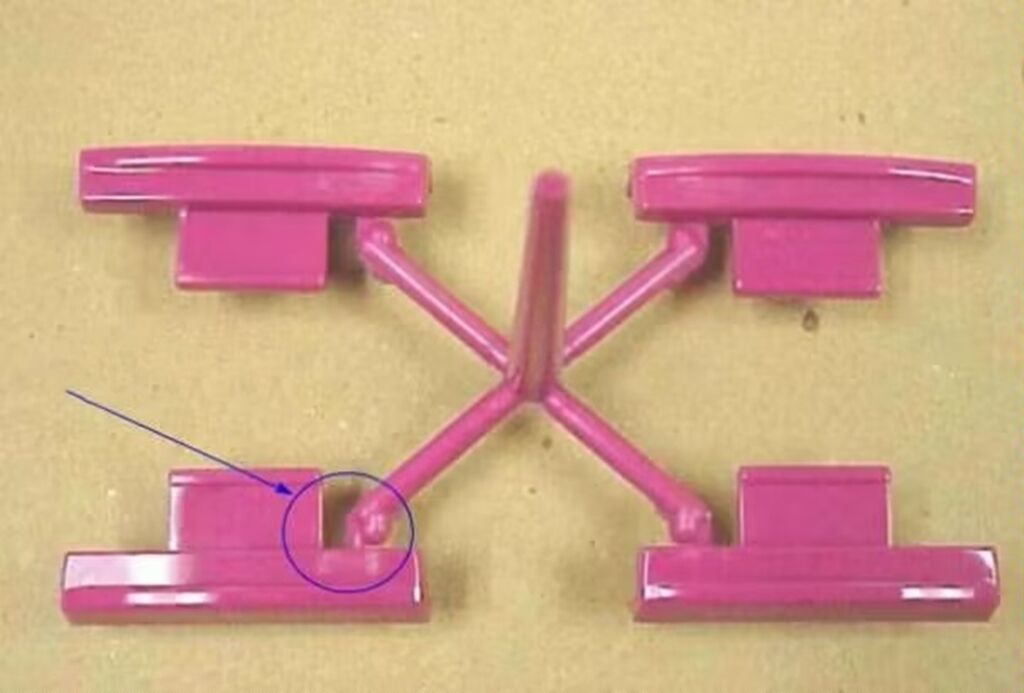

2. The rubber inlet is too thin or too thin, which is also an important factor to cause air and shoot marks. Because the glue inlet is too small or too thin, it will inevitably lead to the glue injection speed of the melt glue entering the mold cavity is too fast, resulting in jet lines and air lines, which is also the cause of snake lines. Therefore, if the problem cannot be eliminated even if the speed has been reduced to a lower level, it is necessary to consider whether the water inlet is too thin or too thin, such as less than 0.5mm or smaller.

3. The thicker the wall thickness of the injection molding part at the rubber inlet, the easier it is to produce air wrinkles, such as more than 4mm. Because the thicker the wall thickness is, the easier it is to generate eddy current when the melt adhesive enters the water inlet, resulting in the generation of air ripple. In this case, it is sometimes difficult to eliminate the air ripple by enlarging the water inlet and reducing the speed. At this time, it is better to change the rubber inlet to a place with a thinner wall thickness, such as a place below 3mm.

4. The brighter the surface of the mold cavity, that is, the brighter the surface of the injection molding part is, the easier it is to produce air wrinkles. If the injection molding part is too bright, slight air lines will be revealed.

5. If the temperature of the melt adhesive or the mold is too low, the injection molded parts will also have the injection lines caused by the gel, accompanied by the mute air lines.

6. For the raw materials that are easy to burn, if the melt temperature is too high, the air ripple caused by too much decomposition gas will occur.

7. The quality of glue should be confirmed. The back pressure of PC material should be set at 10bar~25bar. The speed of glue melting should be set at medium speed. The glue extraction should not be too long. Otherwise, if air is pumped into the gun barrel, the product will have spray. The glue extraction stroke should be set according to the back. The greater the back pressure is, the longer the glue extraction stroke is set, generally 2mm~10mm.

8. The temperature of the nozzle is too high or too low. If it is too high, the rubber at the nozzle will decompose and produce air lines; Too low, the injection is not smooth, forming jet lines, or cold offset printing.

Post time: Oct-25-2022