We know that the products with oil stains on the mold are basically waste products. Most of the mold oil stains are more than 80% of the time, but there will still be 10% – 20% of the mold oil stains. The so-called mold oil stains are not in the mold, but in the materials.For example, some plastic shells, plastic food containers, plastic brackets, etc. should pay attention to this problem.

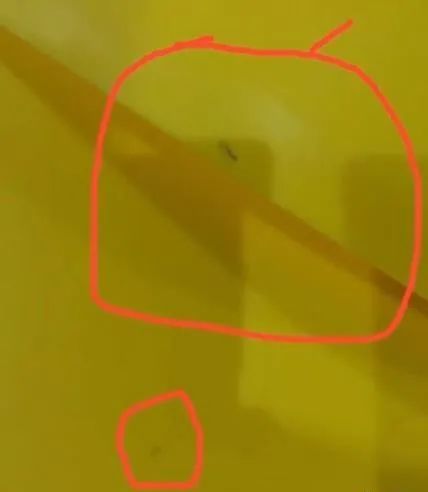

The first is the shape: the oil stain depends on its shape first. The oil stain caused by the mold is a dot, but it is a big one, and the small one is a dot; However, the oil stain caused by the material is produced by the diffusion agent or the low temperature in the phase solvent, so it is generally in the form of a long strip, not a point.

The second is the position: the position of the oil stain on the mold is scattered and not too fixed, but the position of the oil stain in the material is very fixed, that is, it is at the welding line, that is, the last place to exhaust, and its position is relatively fixed.

The third is the frequency: the frequency of the oil in the mold is not certain. Generally speaking, when the machine is started or just maintained, the frequency is higher, and each mold may need to be wiped clean. However, if the oil stain is caused by materials, it is usually fixed, such as every 15 minutes, or every 30 minutes, 40 minutes, and regularly appears at the last place where the air is exhausted at the junction line.

In this case, the three principles can basically be used to determine that it is not the mold itself, but the material. Of course, the most authoritative thing is to do the infrared spectrum analysis.

We should pay special attention to the oil stain caused by this material, especially when there are too many diffusers and fiber solvents, such as toner.

Post time: Oct-28-2022