When winter comes, the temperature is falling all over the country, and in some areas it drops below 0 ℃. In order to avoid unnecessary economic losses, the injection molding machine should be frozen when it is stopped to prevent the water in each element from freezing and causing damage to the element.

Anti freezing measures for shutdown in winter

1. Shut down in winter. When the indoor temperature is lower than zero, the cooling elements on the injection molding machine need to be antifreeze treated.

2. First, turn off the cooling tower, water pump, freezing machine, mold cooling system, etc., and turn off the water source for injection molding machine and auxiliary machine.

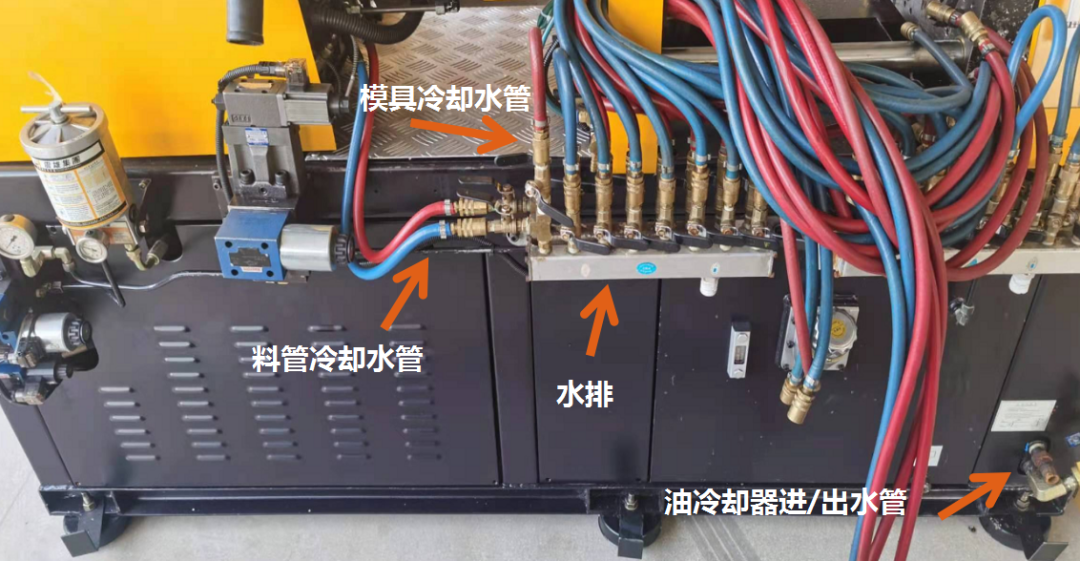

3. The main cooling elements on the injection molding machine are: oil cooler, water drain, water flow distributor, water quality filter, and melt rubber tube cooling system.

4. After turning off the water supply for the injection molding machine, remove the main cooling water pipe, drain the water in the cooling pipe, and then blow out all the residual water in the cooling element with compressed air.

5. When the injection molding machine is used again, reinstall the water pipes and inlet and outlet joints of the cooling elements, and check and clean the water inlet and outlet filter screen of the oil cooler.

Oil cooler section

1. Close the water inlet/outlet valve, remove the cooling water inlet/outlet pipe, fill a container with water, and discharge the oil cooler water.

2. Use a wrench to remove the drain plug of the oil cooler, and then use high pressure air to blow air from the water inlet pipe mouth to make sure that no water flows out of the drain.

3. The water inlet/outlet pipe shall be sealed with a sealing cap, and the drain plug shall be tightened.

Water flow separator

1. Close the water inlet/outlet valve, remove the water outlet pipes of the water flow separator, and use a container to fill water.

2. Loosen all the adjusting handles of the upper and lower rows of the water separator clockwise to the bottom, and drain the water in the water separator.

Water drainage part of injection molding machine

1. Close the water inlet/outlet valve, remove the water inlet/outlet pipe, and fill the water with a container.

2. Open the water inlet/outlet ball valves of the water discharge, and then drain the water discharged.

Cooling water tower

1. Close the water inlet/outlet and make-up valves of the water tower.

2. Open the ball valve at the outlet of the water tower to drain the water from the water tower.

Cooling water tower water pump

1. Turn off the power supply of the water pump motor, and turn off the water inlet/outlet and make-up valves of the tower.

2. Remove the flange screws at both ends of the water pump pipe and drain the water from the pipe.

Water freezing machine

1. Close the water inlet/outlet and make-up valves of the freezing water machine.

2. Open the ball valve at the outlet of the freezing water machine and drain the water in the freezing water machine.

Post time: Dec-30-2022