Due to the high light transmittance of transparent plastics, the surface quality of plastic products must be strict, and there must be no speckles, pores, and whitening. Mist halo, black spot, discoloration, poor gloss and other defects, thus affecting raw materials and equipment during the whole injection process.

The design of molds and even products should pay great attention to and put forward strict and even special requirements. Secondly, because transparent plastics are mostly of high melting point and poor fluidity, in order to ensure the surface quality of products, it is often necessary to adjust the process parameters such as machine high temperature, injection pressure, injection speed, so that the mold can be filled with plastic while injection, and internal stress will not cause deformation and cracking of products.

Preparation and drying of raw materials

Any impurity contained in the plastic may affect the transparency of the product, so it is related to storage and transportation. During the feeding process, attention must be paid to sealing to ensure that the raw materials are clean.

Especially, the raw material contains water, which will cause the raw material to deteriorate after heating, so it must be dried, and the drying hopper must be used for feeding during injection molding. It should also be noted that during the drying process, the input air should be filtered and dehumidified to ensure that it will not pollute the raw material.

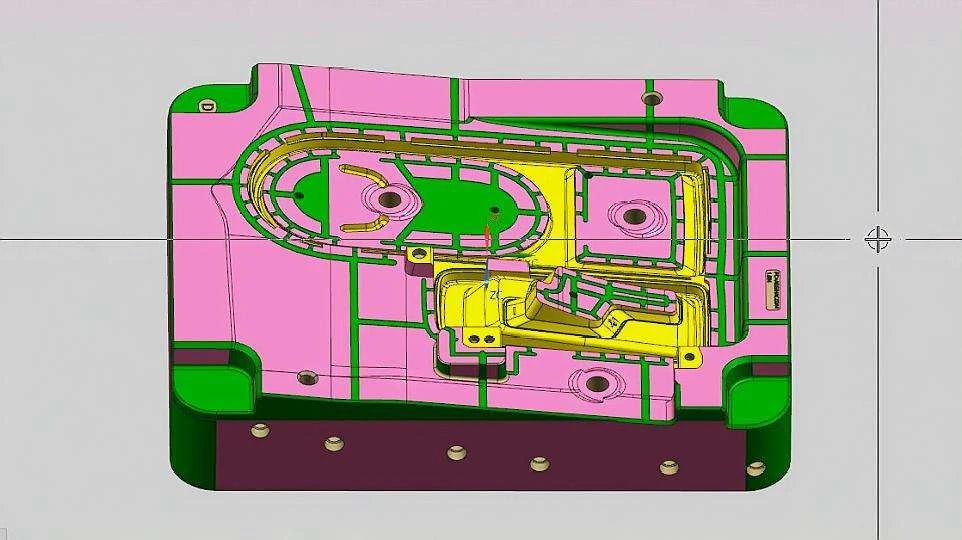

Mold design (including product design)

In order to prevent the backflow from flowing smoothly, or the uneven cooling will lead to poor plastic molding, surface defects and deterioration, the following points should be noted during mold design:

>The wall thickness should be as uniform as possible, and the stripping angle should be large enough;

>The transition should be gradual. Smooth transition to prevent sharp corners. Sharp edges, especially PC products, must not have gaps;

>Gate. The runner shall be as wide and short as possible, and the gate position shall be set according to the shrinkage and condensation process, and the cold material well shall be added if necessary;

>The mold surface shall be smooth and clean with low roughness (preferably less than 0.8);

>Vent. The tank must be sufficient to discharge air and gas in the melt in time;

>Except for pet, the wall thickness should not be too thin, generally not less than 1 mm.

Post time: Feb-14-2023