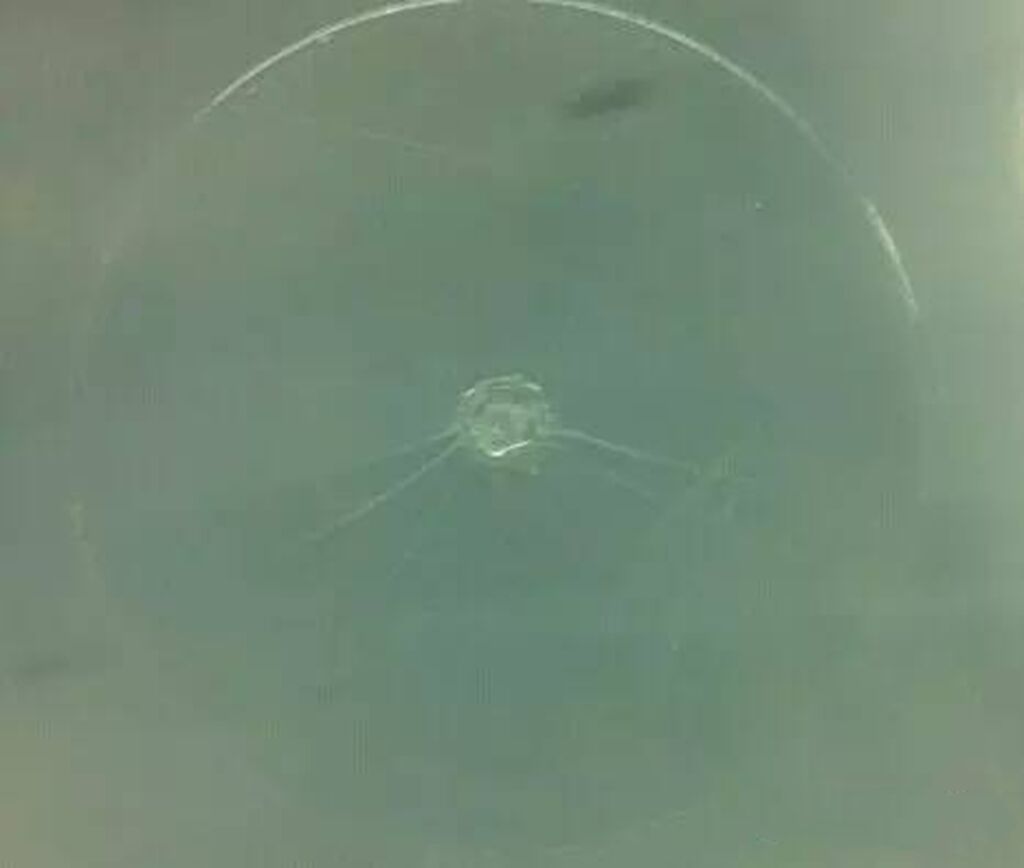

Shattering defect is a typical defect near the gate in injection molding defects. However, many people are confused, unable to identify the defect or make analysis mistakes. Today, we will make a clarification.

It is characterized by cracks radiating from the gate to the periphery, which are deep and generally transparent. In addition, it is not the crack, but the cause of the crack is the anisotropy of the rigid material.

During glue injection at the middle gate, the longitudinal flow strength (tensile strength) of the material is large, while the transverse flow strength (tensile strength) is small. The stress generated by shrinkage will pull the product to fracture, and the fracture must start at the weakest point, that is, the transverse area of the material near the gate with the largest internal stress.

The crack defect is a very serious apparent defect, which is absolutely impossible to pass, so it must be solved. The idea is as follows:

1. About materials

The rigidity of the material is the main reason for the chatter marks, so when there is a long process of large products, try not to choose materials that are too rigid and have low elongation at break, such as GPPS, AS, etc.

In common materials, the order of rigidity from weak to strong, and the possibility of occurrence of seismic crack from small to large is about: PE=>TPU=>PP=>PC=>ABS=>PA=>PVC=>PET=>POM=>PMMA=>AS=>PS.

In general, materials with flexible groups can improve the vibration pattern. For example, rubber materials, SEBS, EVA, K materials are beneficial.

2. About the mold

The gate design of the injection mold is the key. Generally speaking, under the structure with large internal stress and long process flow, the gate vibration pattern is easy to occur. Therefore, for large products, it is easy to adopt the form of multiple gates and wide gates to reduce the rubber feeding resistance and facilitate the flow.

Generally speaking, the point gate is easy to appear vibration lines. Side gate, fan gate and lap gate are slightly inferior. But other gates, such as submersible gate and diaphragm gate, will not be used in such structures. Because most of the products with vibration lines are transparent products, and there is no need to use diving ports or diaphragm ports.

3. About parameters: the measurement of parameters to solve the chatter marks is:

①Slow shooting speed and low shooting pressure

②Short pressure holding time

③The mold temperature must be high, such as PS material. The mold temperature can be set to 60 degrees.

4. Summary

Shattering is a very common defect in the production of transparent products made of GPPS materials. If we do not pay attention to the treatment methods, more than 50% of the defects or all of them may be defective. Only by mastering the above methods can we eliminate the defects and ensure stable and high-quality production.

Post time: Nov-25-2022